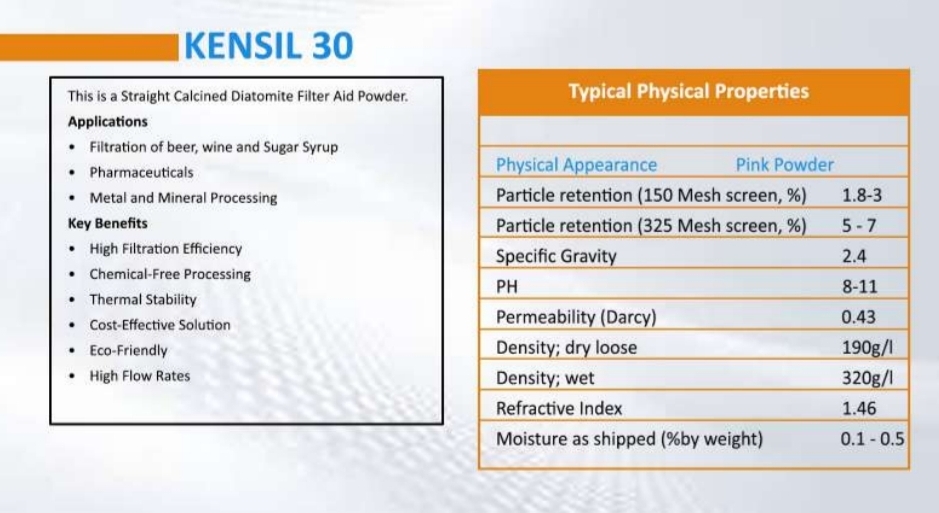

KENSIL 30

Kensil 30 is a straight calcined diatomaceous earth filter powder, specifically designed for the beer and filtration process. This high-performance filter aid is widely used in the brewing industry to provide superior clarification, remove unwanted particles, and help achieve a bright, clean beer with minimal loss of product. Its unique calcined structure is ideal for capturing fine particulates while maintaining excellent flow rates and high filtration efficiency.

How is Kensil 30 Processed?

Kensil 30 is produced from diatomaceous earth that undergoes a calcination process to enhance its filtration properties. Here’s how it’s processed:

- Raw Material Selection: High-purity diatomaceous earth is carefully selected for its consistency and quality.

- Calcination: The diatomaceous earth is heated to high temperatures in a calcining furnace. This process removes water and increases the material’s porosity, creating a highly porous structure with a higher surface area, which makes Kensil 30 highly effective at capturing fine particles.

- Cooling and Grinding: After calcination, the material is cooled and ground to a specific mesh size, optimizing it for filtration efficiency, particularly in applications like beer filtration, where fine and effective filtration is critical.

Kensil 30 Application

Kensil 30 is used primarily in beer filtration as a filter aid to improve the clarity and purity of the beer. Here’s how it’s applied:

- Filtration Process:

- Pre-coating: Kensil 30 is often applied as a pre-coat on the filter media in beer filtration systems. This forms a thin, porous layer on the filter surface that traps unwanted particles such as yeast, hop residue, and other fine solids, ensuring that the beer is clarified without removing essential flavors or compounds.

- Body Feed: In some cases, Kensil 30 may also be added as a body feed to the beer during the filtration process, helping to filter out suspended particles as the beer flows through the filter.

- Applications:

- Beer Clarification: Kensil 30 is widely used in beer brewing to clarify the beer, removing yeast, haze-causing particles, and other solids, resulting in a bright and clear finished product.

- Improving Shelf Stability: The filtration process helps improve the shelf life of beer by removing microorganisms and particles that may contribute to spoilage, ensuring a stable product throughout distribution.

- Minimizing Loss: Kensil 30’s calcined structure ensures that it captures particles efficiently while maintaining high filtration rates, reducing beer loss and improving yield.

Key Benefits of Kensil 30:

- Superior Filtration Efficiency: The calcined structure of Kensil 30 allows it to trap fine particles effectively, ensuring a clearer, higher-quality beer.

- High Flow Rates: Its carefully controlled particle size and structure ensure that beer flows through the filtration system at optimal rates, preventing blockages and reducing downtime.

- Minimal Product Loss: Kensil 30 is designed to provide excellent filtration performance with minimal beer loss, improving yield and making it an economically efficient choice for breweries.

- Improved Beer Quality: By removing yeast and unwanted solids, Kensil 30 ensures the beer maintains its desired flavor profile and clarity, contributing to a consistent, high-quality final product.

- Cost-Effective: Because it reduces the need for frequent filter changes and maximizes filtration efficiency, Kensil 30 offers breweries an economical solution for large-scale filtration.